Our Blog

I want to read about

P3 Audit, a specialist managed service provider of Global Third-Party Payroll Business Continuity and Compliance Testing, today announced that it has entered into partnership with Croner , one of the oldest and most trusted employer support services in the UK. Through this partnership, both P3 Audit and Croner bring added value and a connected service experience to their collective clients. Speaking about the partnership, Paul Holcroft, Managing Director at Croner, said: “We welcome the alliance collaboration with P3 Audit whose UK client base can benefit from our HR, employment law, and health & safety services. This cooperation also offers our clients the potential assurance that their third-party vendors are operating compliantly and without risking business continuity.” “ Croner extends compliance and business continuity to our clients who have welcomed work from home as a critical part of their operations, without realising the obligations and risk assumed by employers” said Chris Els, CEO of P3 Audit. “While P3 Audit focus on testing vendor business continuity as well as contract SLA compliance, we are proud of our partner collaborations that ensure extended business resilience for our clients.” To learn more about the P3 Audit expertise in Business Continuity Plan testing, or to discuss how you can maximise and galvanise your third-party vendor relationships, contact us today!

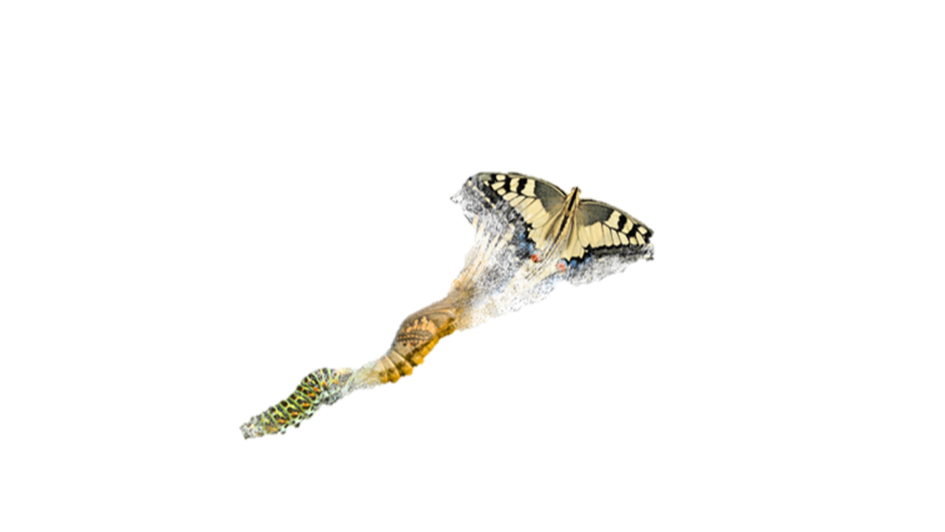

Change is certain. If we can accept the certainty of change then we can be open to its predictability. If we can predict change, we can prepare for it. If we are prepared for change then we will no longer resist it, but rather anticipate it and take advantage of it. In outsourced relationships our success depended on collaborating with downstream professionals to fulfil functions where we were not the experts. It is rare that a client will have contact with a subcontractor or even be aware their services are outsourced further downstream. Regulatory compliance, especially relating to data security and privacy, is shining a light on the need for greater transparency in supply chain relationships. Accepting responsibility for the success of “change” means also taking accountability for user onboarding, user adoption, and successfully implementing new ways of doing things. This invariably means including new technology to empower new processes. When implementing something new, it is as important to sunsets the "old" as quickly as possible. Measures of success remain strategic business ambitions that initiated the change. Change management has been a critical part of any new technology adoption and, most importantly, in any implementation project. Investments in technology, new processes, and new people/talent are made precisely to effect change. If change is not required, then its simple - do nothing. If one is going to invest in Change, lets ensure Change Management is considered and committed to first. Consider Change Managers the Architects of Success. Controversial maybe, but if Change Managers have ownership of design, then let them be accountable for what technology, processes and people will be required to achieve the change. At very least ensure they are included in any proposed investments in change and its associated spend – people, processes, and technology. Change Management is a strategic function. A lack of investment in Change Management will lead to projects failing. Look a bit closer and one might find downstream processes and supply partners are left out of the Change Management process, and can be the point of failure of any new technology and processes being implemented. The basic principles of supply chain can be overwhelming. In any one process, there can be hundreds of downstream suppliers of product and services. These “unknown” participants can introduce threats to a program’s success, and ultimately risk a customer’s business continuity. Neglecting to include participating third parties in any change management program will prove costly. I was fortunate to meet up with Michele De Kreek of Up-Time Consulting. This specialist change management consultancy understands third parties’ impact and the importance of including them in any change management process. I asked Michele to demystify the function of change management for me:

The term forensic refers to the application of scientific knowledge to legal problems, especially scientific analysis of physical evidence (as from a crime scene). Third-party process forensics looks to discover legitimate partnerships, their process practices and industry compliance to protect everyone in the shared supply chain.